S7 Technics extended the scope of EASA Part-21 J certificate to perform modifications and repairs of aircraft water and waste systems

S7 Technics’ DOA (Design Organisation Approval) developing technical documentation for repairs and modifications of water and waste systems installed on aircraft

The scope of works during aircraft base maintenance visit includes repair of various systems, which is carried out in accordance with documentation of the aircraft manufacturing companies (AMM, SRM etc).

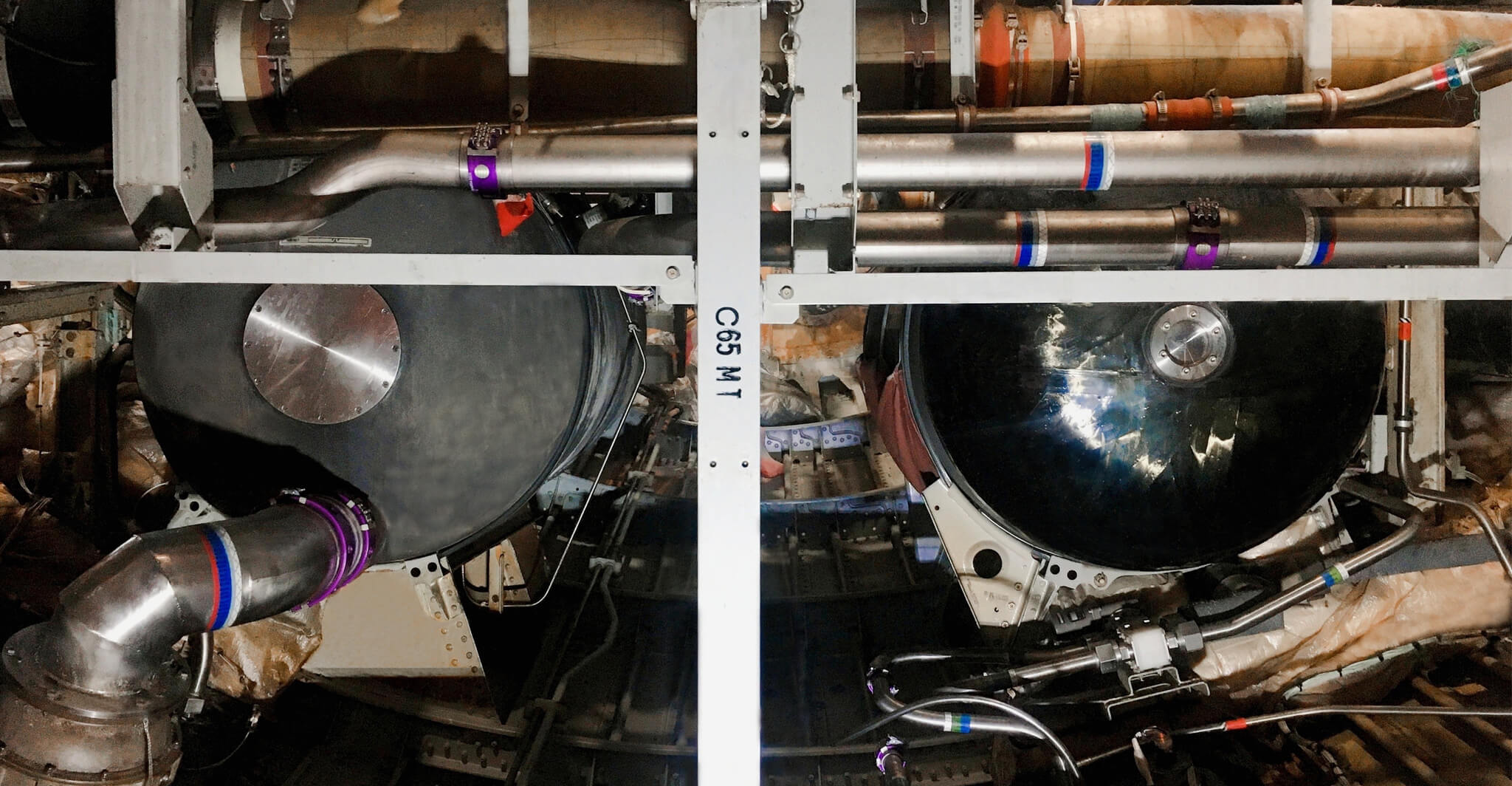

However, there are some unusual damages which sometimes detected during maintenance and that are not described in the aircraft maintenance documentation. Such cases, for example, include cracks in the tanks of toilets and water systems. In this situation, the MRO provider must request repair instructions from the aircraft manufacturer or in some case order a new component to replace the old one. But each of these options involves significant financial and time costs.

In the way of cost optimization and reducing the time frame of maintenance, S7 Technics’ DOA received an extension of Part-21J certificate scope to perform design works on water and waste systems (ATA 38), which gives an opportunity to design modifications and repairs for all components of these systems: pipelines, water systems of galleys and toilets, water tanks, waste tanks and other.

The certificate extension required the necessity to pass an EASA audit, which included the staff competence checking, as well as the checking of the ability to perform this type of works. Due to the opportunity to design modification and repairs under its own design approval, S7 Technics reduces the time for repair of damaged components.

“This service is definitely topical to the current situation in the aviation industry. After all, it is quite difficult to order new components now – delivery takes a long time. And the ability to develop repair documentation by the S7 Technics’ DOA allows us to repair aircraft in the shortest time. Reducing the duration of repair work directly affects the reduction TAT (turn-around-time),” commented Artem Akhmedov, Deputy CEO – Part-21 Accountable Manager, S7 Technics.

S7 Technics’ DOA can develop modifications and repairs for all types of transport category aircraft certified by EASA.

Company news

2021 for S7 Technics, Russia’s leading aircraft MRO provider, was the year of breaking new ground and adding new operations and services to its capability list. Gradual recovery of Russian airlines’ flight hours translates into increasing volumes of MRO.

S7 Technics among the first MRO organizations in Russia started offering redelivery checks several years ago as a comprehensive one-stop-shop service. S7 Technics chief engineer Leonid Shoshin and sales director Nikita Belykh told about the experience in completing redelivery checks the provider has accumulated during the pandemic.

S7 Technics, Russia’s leading provider of aircraft maintenance, repair and overhaul (MRO) services has launched a new facility within its cabin interior repair shop, which is part of the company’s maintenance base at Moscow Domodedovo Airport (DME).

S7 Technics, Russia’s leading aircraft maintenance, repair and overhaul (MRO) service provider, announces the launch of the production of polyurethane foam cushions for aircraft seats (seats, backrests and headrests).